WT-II Type Flip-Plate Filter Pool Water Distribution and Aeration Process Package

Product advantages

Product Classification:

Key words:

WT-II Type Flip-Plate Filter Pool Water Distribution and Aeration Process Package

Overview

The flip filter pool is a relatively new type of filter pool filtration and backwashing water distribution system both internationally and domestically. It has made new technological breakthroughs in backwashing systems, drainage systems, and filter material selection, resulting in significant improvements in effluent water quality, reduced backwashing water volume, shorter backwashing time, longer backwashing cycles, lower infrastructure investment, lower operating costs, and simpler construction with shorter construction periods.

Product Structure

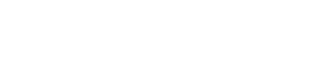

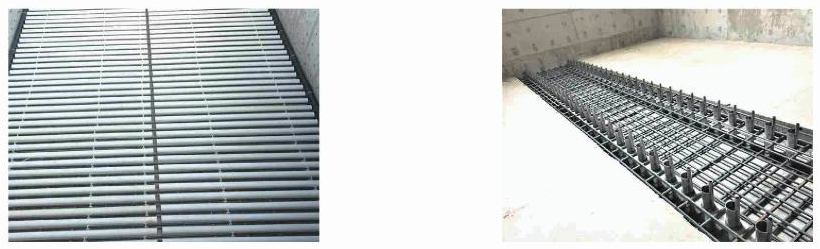

The water distribution and aeration system consists of transverse water distribution and aeration pipes, longitudinal water distribution pipes, and longitudinal aeration pipes, with the longitudinal water distribution and aeration pipes welded into one.

Product Features

1. The transverse water distribution and aeration pipes are made of ABS engineering plastic, prefabricated, and have good durability. The hydraulic conditions are stable.

2. The longitudinal water distribution and aeration pipes are made of stainless steel 304, which is corrosion-resistant and easy to install.

3. This water distribution system adopts a low-resistance water distribution system and a high-resistance aeration structure. During backwashing, air and water are cut by the gravel support layer, making the water distribution and aeration more uniform, while enhancing the shear, friction, and collision effects on the filter material, making backwashing more thorough, extending the filtration cycle, improving effluent water quality and quantity, reducing filter pool operating costs, and facilitating construction management.

4. Using this water distribution system to configure the filter pool allows for a lower installation height, which can increase the height of the filter material layer, enhancing the deep interception capacity of the filter material and improving the effluent water quality.

Main Performance of the Product

Longitudinal Water Distribution Pipe

| Project | Content | Remarks |

| Specifications | D89x3 L=990 | Length can be made according to design requirements |

| Material | Stainless Steel 304 | |

| Installation Requirements | Pipe mouth elevation error ±2cm |

Longitudinal Aeration Pipe

| Project | Content | Remarks |

| Specifications | D30x2.5 L=590 | Length can be made according to design requirements |

| Material | Stainless Steel 304 | |

| Installation Requirements | Pipe mouth elevation error ±2cm |

Transverse Water Distribution and Aeration Pipe

| Project | Content | |

| Specifications (Length x Width x Height) | 2830x161x185(mm) | Length can be made according to design requirements |

| 2830x138x169(mm) | ||

| Material | HDPE Engineering Material Stainless Steel 304 |

|

| Pipe Wall Thickness | 38N/cm2 | |

| Allowable Pressure Strength | 5mm (Plastic) 2mm (Stainless Steel 304) |

|

| Aeration Hole Diameter | 2.5-3.5mm | Open holes according to design requirements |

| Water Distribution Hole Diameter | 15-20mm | |

| Filter Pool Opening Ratio | 0.8-1.25% |

Working Principle

The function of the WFB type filter pool water distribution and aeration system: evenly collects water during filtration, and evenly distributes backwashing inflow and backwashing air during backwashing. The combined air-water backwashing process of the filter pool consists of three steps: single air backwashing, combined air-water backwashing, and single water backwashing. During single air backwashing, air enters each transverse pipe through the longitudinal aeration pipe, and is then evenly distributed into the filter material through the air holes on the side and top of the transverse pipe; during combined air-water backwashing, air and water enter the water distribution and aeration chamber simultaneously, forming a uniform air cushion layer at the top of the water distribution and aeration chamber (bottom of the support plate). Air enters the transverse pipe through the longitudinal aeration pipe, while water enters through the longitudinal water distribution pipe. The air and water entering the transverse pipe are evenly distributed, forming an air cushion layer in the transverse pipe, with air being evenly distributed through the exhaust holes at the top and middle of the transverse pipe, while water is evenly distributed through the water distribution holes at the bottom of the transverse pipe; during single water backwashing, water enters the transverse pipe from the longitudinal water distribution pipe and is evenly distributed before entering the filter material through the water distribution holes at the bottom of the transverse pipe. Since an air cushion layer is formed simultaneously in the water distribution and aeration chamber and the transverse pipe during combined air-water backwashing, it ensures the uniformity of water distribution and aeration, improving the backwashing effect.

Related Products

This type of inclined plate has been widely used in Japan for many years.

This type of inclined plate has been widely used in Japan for many years.

This type of inclined plate has been widely used in Japan for many years.

Product Consulting

Dear customers, if you have any comments and suggestions on our products or services, please tell us in time, we will give you satisfaction as soon as possible

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.