WT - New Type Deep Bed Denitrification Filter Process Package and Air-Water Distribution Filter Brick

Product advantages

Product Classification:

Key words:

WT - New Type Deep Bed Denitrification Filter Process Package and Air-Water Distribution Filter Brick

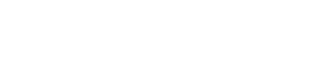

Denitrification Deep Bed Filter Pool

The denitrification deep bed filter pool is a wastewater treatment unit that combines biological deamination and filtration functions. It uses specially sized and shaped quartz sand as the medium for denitrifying microorganisms, while the deep bed effectively removes nitrate nitrogen (NO3-N) and suspended solids. In the presence of an external carbon source, the denitrifying bacteria attached to the surface of the quartz sand convert NO3-N into N2, completing the deamination process. The denitrification deep bed filter pool integrates multiple functions, including physical retention of suspended solids (SS), chemical micro-flocculation for phosphorus removal (TP), and biological denitrification for nitrogen removal (TN).

In the presence of an external carbon source, the deep bed denitrification filter pool can remove TN, SS, and TP. Without the external carbon source, it functions as a deep bed filter that can simultaneously remove SS and TP.

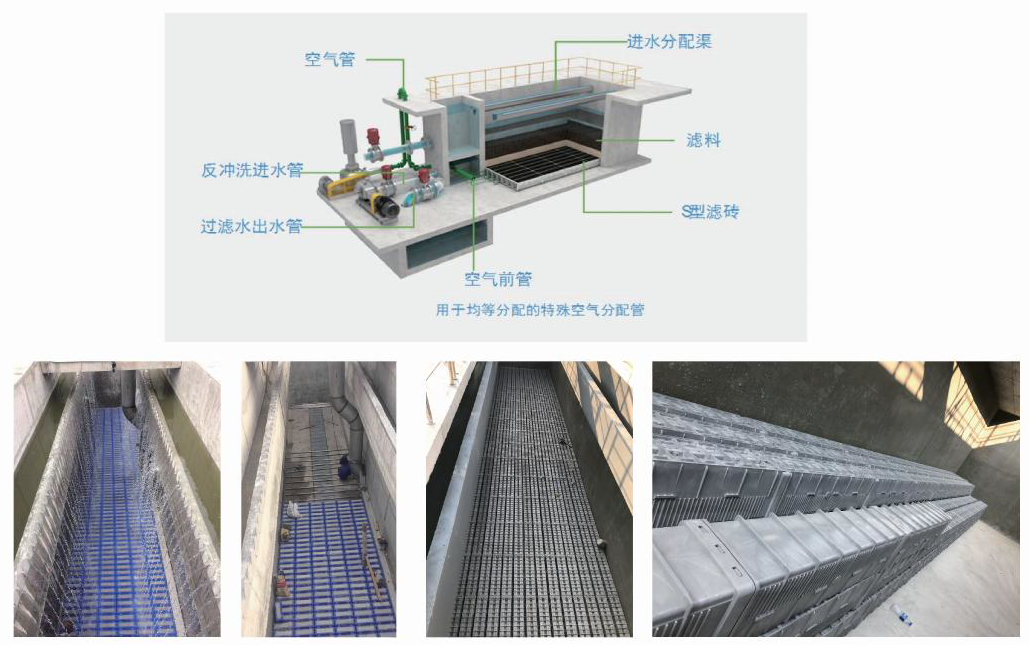

Deep Bed Filter Pool Air-Water Distribution Filter Brick

① Overview

Based on the advanced technology of air-water distribution filter bricks from foreign deep bed filter pools, we have developed the WTLZ type high-density polyethylene filter brick, which is applied in the denitrification deep bed filter pool and other air and water backwashing and single water backwashing filter pool distribution systems.

The WTLZ type high-density polyethylene filter brick adopts a secondary water and air distribution structure, with an eight-shaped cavity set in the middle of the rectangular filter brick. The inner side of the eight-shaped cavity serves as the primary water and air distribution channel, while the outer space of the eight-shaped cavity serves as the secondary water and air distribution channel. During backwashing of the filter pool, air and water first enter the primary water and air distribution channel, and after being evenly distributed through the primary distribution holes, they then enter the secondary distribution channel.

On the upper sides of the primary water and air distribution channel, there are evenly distributed upper and lower layers of air intake holes. The top of the air intake holes forms an air flow channel, creating a sufficiently thick air cushion layer, with the bottom of the air cushion layer aligned with the horizontal line of the air intake holes to ensure that all air holes can intake air evenly. The opening ratio for primary air distribution is 0.09%-0.11%, and the water head loss generated by the air holes is calculated using the formula H=1.05X10-4V2, where v is the flow velocity in m/s, and H is measured in meters.

On the lower sides of the primary water and air distribution channel, there are evenly distributed primary water distribution holes. To ensure uniform water distribution, the opening ratio for primary water distribution is 0.5%-0.7%, generating a certain amount of water head loss during distribution, aiming to minimize the difference in primary water distribution between the front and rear sections of the filter brick.

At the top of the filter brick, there are secondary water and air distribution spray holes, with an opening ratio of 0.5%-0.9%. The secondary air and water distribution can correct the uneven water distribution caused by changes in flow velocity and along the way water head loss during primary water distribution, ensuring uniform air and water distribution throughout the filter brick in the entire speed pool, thus achieving good cleaning results during backwashing.

② Product Structure Features

The filter bricks are connected using a plug-in connection, sealed with O-ring rubber water stop rings at the connection points to ensure no water or air leakage.

Easy to install and maintain, assembled into a single row according to the length of the filter pool, with the entire length laid into the pool, allowing for quick installation and cost savings.

③ Technical Specifications

Stability: Non-toxic, odorless, acid and alkali resistant, UV resistant

Mechanical strength: Withstands 3.8KN for 3 minutes without deformation or cracks

Low and high temperature resistance: Applicable range -20°C to 80°C

Opening ratio: 0.5%-0.9%

Backwashing intensity: Water flushing intensity 4-8L/S.m2, air flushing intensity 12-25L/S.m2

Primary air distribution opening ratio: 0.09%-0.11%

Primary water distribution opening ratio: 0.5%-0.7%

Secondary water/air distribution opening ratio: 0.5%-0.95%

④ Specifications

| Model Dimensions | Height H (mm) | Width B1 (mm) | Height B2 (mm) | Length L1 (mm) | Length L2 (mm) | Hole diameter (mm) | Number of holes (pcs) |

| WTLZ-I Type | 305 | 270 | 280 | 1220 | 1268 | 5.25 | |

| WTLZ-II Type | 380 | 360 | 370 | 865 | 940 | 5 |

Related Products

This type of inclined plate has been widely used in Japan for many years.

This type of inclined plate has been widely used in Japan for many years.

This type of inclined plate has been widely used in Japan for many years.

Product Consulting

Dear customers, if you have any comments and suggestions on our products or services, please tell us in time, we will give you satisfaction as soon as possible

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.