WT - New High-Efficiency Sedimentation Tank Process Package

Product advantages

Product Classification:

Key words:

WT - New High-Efficiency Sedimentation Tank Process Package

Overview

The efficient sedimentation tank is developed based on various theories such as sludge coagulation, circulation, inclined tube separation, and concentration. Through reasonable hydraulic and structural design, it integrates the functions of sludge-water separation and sludge concentration into an external reflux type solid particle contact clarifier. It is mainly used to remove solid suspended matter, turbidity, organic matter, and heavy metals from water.

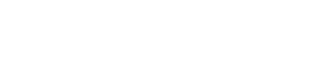

Process Flow

① Coagulation Mixing Zone

Coagulants are added to the raw water, and under the action of a rapid stirrer, they quickly mix with the suspended solids in the wastewater. By neutralizing the negative charge on the surface of the particles, the particles become "destabilized," forming small flocs that then enter the flocculation tank. At the same time, phosphorus in the raw water reacts with the coagulant to form phosphates, achieving the purpose of chemical phosphorus removal.

② Flocculation Zone

The coagulated raw water is fully mixed with the recycled sludge and flocculant to enlarge the flocs. The slow stirrer ensures that the reagents and flocs are fully mixed without destroying the already formed large flocs.

③ Inclined Plate Sedimentation Zone

After flocculation, the large and heavy flocs sink directly and further concentrate. The small and light flocs are intercepted and gathered by the inclined tubes. The sludge slides down the surface of the inclined plates and settles at the bottom of the sedimentation tank. Then, a circulation pump transports part of the sludge back to the coagulation and flocculation tanks, while the remaining sludge flows to the sludge treatment system by gravity. The supernatant is collected and discharged by a stainless steel collection tank located at the top of the inclined plate sedimentation tank.

Technical Features

Recycling of flocs can save 10%-30% of chemicals;

The sedimentation zone is arranged with inclined tubes (plates), which enhances the sedimentation effect and improves the quality of the effluent;

The floc density is high and homogeneous, greatly increasing the sedimentation speed of the system, with a surface load of 15~25m3/mh, saving 80% of the land area;

The concentration of the discharged flocs is high, allowing for direct dewatering without the need for concentration treatment in a concentration tank;

The use of floc recycling technology effectively ensures the concentration of flocs in the system, making the system resilient to shock loads;

High treatment efficiency, large water production per unit area, small footprint, low civil investment, especially suitable for renovation and expansion projects;

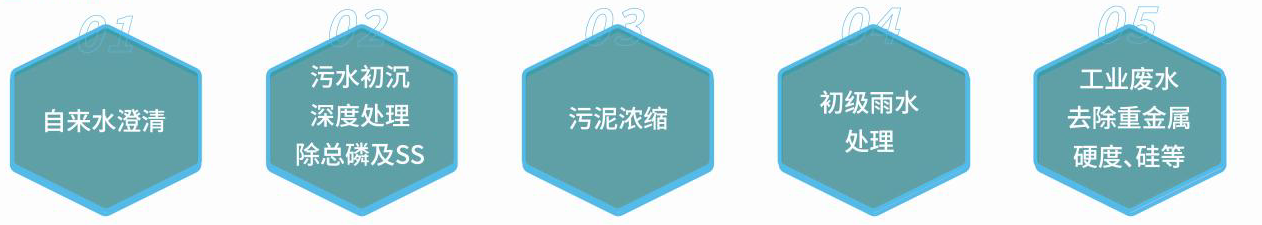

Application Fields

Related Products

This type of inclined plate has been widely used in Japan for many years.

This type of inclined plate has been widely used in Japan for many years.

This type of inclined plate has been widely used in Japan for many years.

Product Consulting

Dear customers, if you have any comments and suggestions on our products or services, please tell us in time, we will give you satisfaction as soon as possible

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.